Modern AC drives are based on solid state electronics technology. Preventive maintenance is required to operate this AC drive in its optimal condition, and to ensure a long life. It is recommended to perform a monthly check-up of the AC drive by a qualified technician.Before the check-up, always turn off the AC Input Power to the unit.

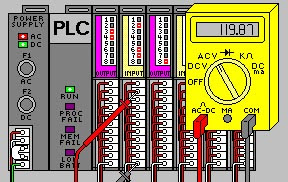

Wait at least 2 minutes after all display lamps have gone out, and then confirm that the capacitors have fully discharged by measuring the voltage between B1 and Ground using a multi meter set to measure DC.

Periodic Inspection:

Basic check-up items to detect if there were any abnormality during operation are:

1. Whether the motors are operating as expected.

2. Whether the installation environment is abnormal.

3. Whether the cooling system is operating as expected.

4. Whether any irregular vibration or sound occurred during operation.

5. Whether the motors are overheating during operation.

6. Always check the input voltage of the AC drive with Voltmeter.

Periodic Maintenance

! WARNING! Disconnect AC power before processing!

1. Tighten and reinforce any screws of the AC drive if necessary because they might loose due to vibration or temperature changes.

2. Check the conductors or insulators for corrosion and any physical damages.

3. Check the resistance of the insulation with Mega-ohm meters.

4. Frequently or regularly check the capacitors, relays and change if necessary.

5. If use of the AC drive is discontinued for a long period of time, turn the power on at least once every two years and confirm that it still functions properly. To confirm functionality, disconnect the motor and energize the AC drive for 5 hours or more before attempting to run a motor with it.

6. Clean off any dust and dirt with a vacuum cleaner. Place special emphasis on cleaning the ventilation ports and PCBs. Always keep these areas clean, as accumulation of dust and dirt can cause unforeseen failures.